Laser Printer Decals

Iron oxide, a common colorant in clay and glaze is also prevalent in the toners of many laser printers. Hewlett Packard ink cartridges, for instance, contain up to 60% iron oxide. Iron oxide helps the toner hold its magnetic charge on the printer’s drum. The iron oxide, heat-resistant enough for the laser printing process is also resilient enough to handle the high temperatures of a ceramics kiln. The toner’s other pigments and fillers burn off, leaving the iron oxide to decorate the ceramic piece with rich dark brown designs.

STEPS

- Create a print-ready document with desired images.

- Print from laser printer onto decal paper (remove tissue paper if any is attached; print on the shiny side).

- Cut out image from paper close to the edge.

- Dip image in bowl of water and wait till paper softens.

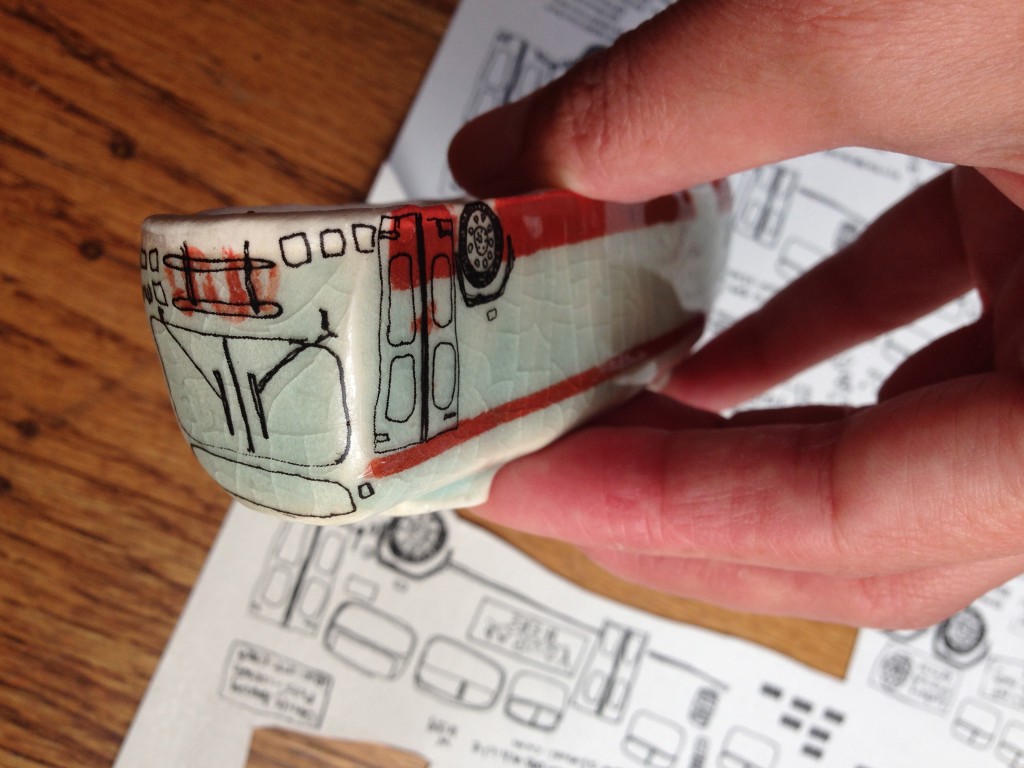

- Slide the image off its backing paper and onto your ceramic piece.

- Insure decal image is flat against glaze-fired ceramic piece (no bubbling or puckering).

- Fire in an electric kiln.

PRINTERS

I use an old Hewlett Packard laser jet (HP 4100 DTN).

If you’re going to purchase a new printer, I recommend the Canon imageCLASS LBP6000 Compact Laser Printer, which is around $100: http://www.amazon.com/gp/product/B004BDMP8M

Frank Gaydos’s article below cautions against NEC and Brothers printers.

Rothshank’s website says the following will work:

- HP LaserJet M1212nf MFP

- HP LaserJet 1022

- HP laserjet 4L

- HP laserjet 5L

- HP P1005 laserjet

- HP P1006 laserjet

- Printers that accept HP LaserJet print cartridge 12A or 85A

PAPER

Laser Waterslide Decal Paper from www.beldecal.com

- Color: Clear Paper

- Direct link: http://www.beldecal.com/laser_paper.html

FIRING

Decal firing temperature varies depending on glaze firing temperature. You want the glaze to flux a bit, but without absorbing the decal.

- I glaze fire to cone 10 and decal fire to cone 1.

Handy chart from Arbuckle’s article below:

On china paint: c020-c/018

On low-fire glaze: c/010-c/06

On cone 6 glaze: c/04-c/1

On cone 10 glaze: c/04-c/6

On terra sigillata: to at least c/04, a bit higher on burnished sigillata

GLAZES

Glaze consistency sometimes changes in the firing. Testing is the best way to see what works for you.

Arbucke’s experience is that clear glazes with high Gerstley borate or nepheline syenite tend to “eat” the image.

Rothshank notes that glazes with iron as the main colorant (celadon / temmoku) do not remain consistent (I use celadon and have good results about 80% of the time.) and glazes with tin can be prone to pinholes.